Wood Cutting Service

Wood has qualities that allows it to be graded on its durability affecting its cost.

Elements such as knots, heartwood, softwood and hardwood are often examined when pricing the wood. These qualities allow the material to be graded on how durable and strong it is consequently affecting the price of it and its uses.

Before purchasing wood for CNC cutting let’s have a look at the wooden elements that may affect the price and the cutting process.

Wooden knots are formed when a growing tree is enclosing the old branches that died off or new buds that were only beginning to form. The patterns formed by wooden rings growing round the knots create a visual appeal in the use of furniture, floors and other attributes of interior applications. The position, size, number and condition of the knots will affect the strength of the wood and determine its appropriate uses in construction.

When purchasing a piece of wood that contains knots our CNC specialist will advise you on the best approach. They will make sure that the knots are aesthetically positioned without compromising the strength of the material.

Get a Quote — OR CALL (01) 430-1250

Wood Cutting Dublin

As wood progresses to grow the centre part of it naturally dies off and becomes more resistant to decay. This centre part of the tree that no longer has a function of supplying the tree with water is known as heartwood. It can be darker in colour and visually appealing in interior use and is more durable than the wood that is still alive.

Hardwood and softwood determine whether it’s a slow growing or a fast growing tree.

It’s a type of wood that is harder to cut. It will splint if a nail is pounded into it and may involve a more complicated cutting process on a CNC. Softwood, such as pine tree, is a more flexible type of wood and is easier to work with.

Bearing these details in mind you should be aware of the fact that the harder the wood the longer it will take to cut it. A CNC machine is designed to cut flat sheets of wood. If a piece of wood is not in a flat sheet it will result in a complicated and expensive service.

A CNC wood cutting service is charged by the hour. This is because for example, a design will take more skill and time to cut a complex piece of material.

Let us bring your idea to life in MDF, plywood, solid wood, wood veneer and more. Get in touch with us for a quote and let's get things moving!

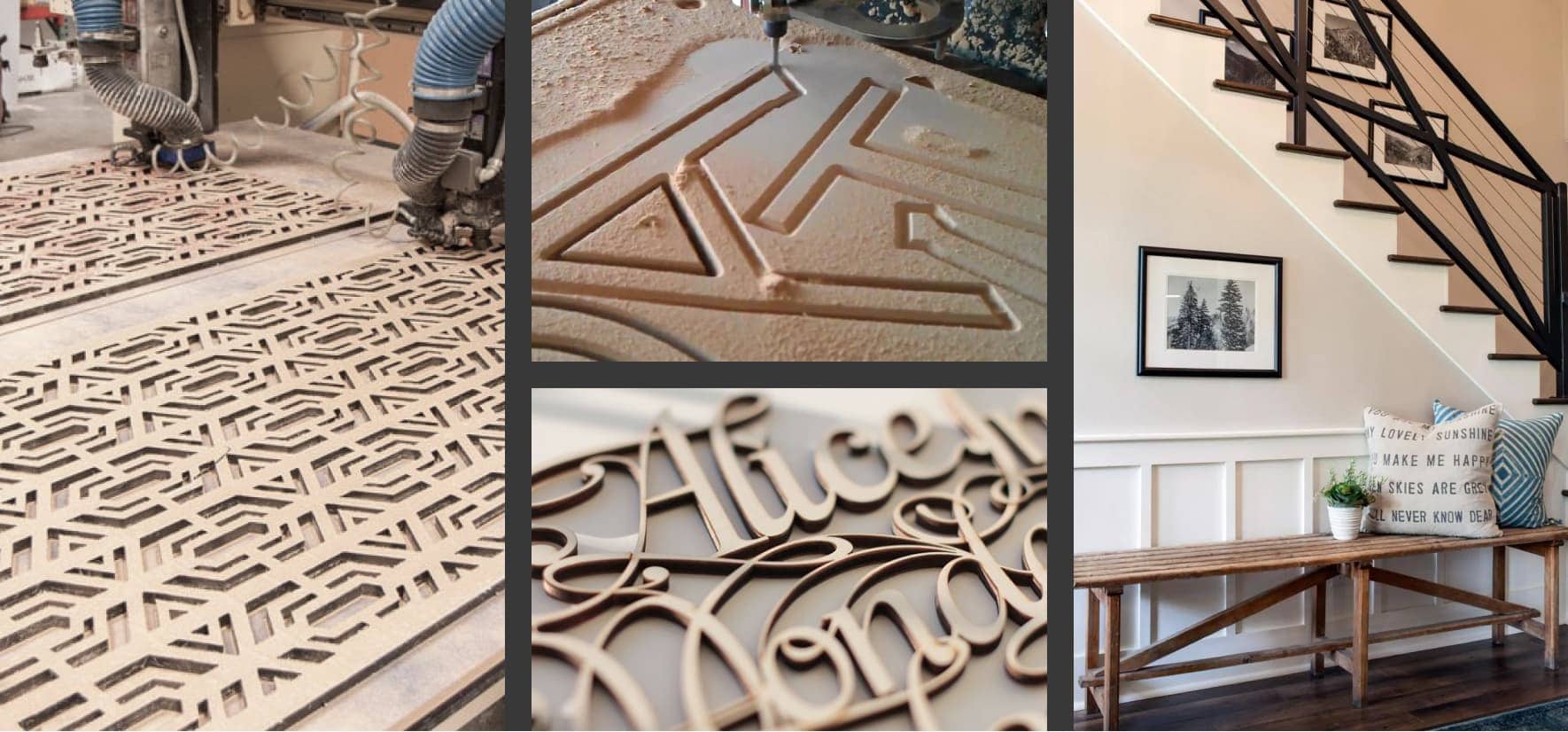

MDF Cutting

A CNC router is a computer controlled cutting machine used for various different materials including MDF. This technique allows the process of cutting material to be more precise and expedite the production time. A CNC router uses flat sheets of material to cut out desired shapes. It can be programmed to reproduce patterns and designs for large orders.

There are different types of materials that are commonly used on a CNC machine.

MDF is formed through a chemical compression of much smaller wooden particles. A water resistant version of it would be known as HDF.

HDF is a denser version of MDF and its moisture resistance treatment will give the material a longer lifespan and may prevent it from warping and swelling.

You’d be surprised to know that most of your home furniture is made of MDF or a slight variation of it such as plywood.

After a short consultation with our CNC specialist you’ll be able to pick the most suitable variation of MDF material based on your budget and purpose.

There are different purposes for MDF that include domestic and commercial uses.

MDF Cutting on a CNC Router

In domestic applications you’ll see furniture such as rad covers, kitchen cabinets and wall panels all made out of MDF. In commercial uses MDF materials will be used for indoor and outdoor signage and other branding such as exhibition stands. Sometimes entire pieces will include parts that were cut on a CNC machine.

Commercial uses of CNC may involve signage that will be displayed outside. For this use you will find tricoya to be one of the most durable materials.Tricoya is an extremely water resistant type of MDF. Its exterior applications brings the swelling of the material to a negligible level.

OSB is another type of material that is becoming popular in interior design. It’s uses are no longer restricted for roof sheathing, flooring and walls. It is widely used to construct domestic and commercial cabinetry due to its unusual, rich texture. A custom made osb piece of furniture is a gateway of creating an outstanding feature in a home.

CNC cutting service is priced per hour of cutting time or design work. The type of material and the complexity of a design can affect the cutting time. This is because different types of materials can be more complex to cut. For example, MDF will be cut faster than Plywood due to the difference in their physical composition.

Did you know that a lot of parts for furniture like bunk beds are cut using CNC router and most likely will be cut from MDF material. To view more of our bunk bed selection click here

Timber Cutting

Timber is defined as wood obtained after the tree has been cut. Timber can come as softwood and hardwood. Hardwood, like beech wood, would generally mean that it comes from a slow growing tree, it is harder to cut and will splint if a nail was pounded into it. Softwood, like pinewood, comes from a quick growing tree and is easier to work with without splitting easily unlike hardwood.

Timber comes in different densities and has a structure which includes knots that may affect the quality and value of timber when used for construction purposes. Timber has an ability to expand and shrink based on the environmental conditions such as moisture and temperature.

A CNC router is a computer controlled machine used for cutting material in sheets. Our CNC cutting services are based on hourly rate. This is because the same pattern can vary the amount of labour and machine time on different types of material. Timber has a more complicated structure than MDF or plastics and if approached quickly and without care, it can splintered.

Timber CNC Router Cutting

When choosing timber for your project it is important to understand the exact type of its exploitation. Under proper conditions, timber can have a long life and an outstanding performance. However if timber is applied and treated incorrectly it can cause various different decaying issues such as fungal activity, dry rot and insect damage. Choosing timber can provide a beautiful aesthetic appeal due to its natural grain and colour.

Our CNC specialist will be able to advise you on finishing options and provide a fitting service if needs be. Did you know that our cabinet makers use CNC cutting services to create parts for custom made furniture.

What Woods Can You Cut?

Wood Types for Milling

MDF

HDF

Timber

OSB

Veneer

Plywood

We manufacture wood (MDF, Timber, etc.) products based on any idea or design. Get in touch and let's make your project a reality!